A strong Intel is what the tech industry needs right now

[ad_1]

Yesterday, while watching Intel’s new CEO lay out his plan for the company’s future, I started thinking back on the last 15 years of tech. In 2005 I owned a smartphone powered by an Intel processor. The was, like every smartphone in 2005, not great, but it was fully functional, well-received and powered by an XScale ARM chip. A year after I bought the Magician, Intel for $600 million, believing it would have an ultra-efficient (0.5W!) x86 CPU capable of running Windows Vista by 2010. Last quarter, 6.7-billion ARM-based chips were sold inside phones, laptops, games consoles and thousands of IoT devices. Intel has yet to release a 0.5W CPU capable of running Windows Vista.

In 2010, Apple released the iPad, an ARM-powered tablet computer. Two years later, Microsoft released Windows RT, . At the same time, Intel was pushing its Atom x86 processors for phones and tablets, with limited success. It continued to struggle to compete with other companies’ low-powered designs, resulting in Microsoft taking , and Apple switching to for laptops and desktops.

In 2017, two years after Intel failed to deliver on its 2015 target for 10nm processors, Qualcomm, Apple, Samsung and others started shipping 10nm chips. These were not as technologically advanced as Intel’s proposed CPUs, but were nonetheless more dense than what Intel had to offer. By mid-2019, AMD, Intel’s main rival in the PC space, was selling processors built on TSMC’s 7nm process, which is broadly equivalent to Intel’s 10nm offering. Intel didn’t ship a 10nm chip until late 2019 and, as of writing, only a handful of 10nm Intel processors are found inside laptops, while its desktop chips are still on 14nm.

In the past few years, AMD has more-than doubled its CPU market share. Meanwhile, Qualcomm has a near-monopoly on the chips inside Android smartphones. Apple is transitioning away from Intel CPUs in its products, switching to its own chips fabricated on TSMC’s industry leading 5nm process.

All of which is a convoluted way to say, Intel is not in a good place and it doesn’t have anyone to blame but itself. The past 15 years have been like watching a freeway pileup in ultra slow motion, with poor decisions compounded by and negatively impacting others, as Intel has gone from being dominant to selling off divisions and playing catch up.

Pat Gelsinger knows that. Gelsinger worked on the legendary 386 CPU and went onto be the lead architect for the 486, which saw Intel through to the Pentium era. After a stint as chief technical officer from 2000 to early 2005, he left Intel in 2009, before returning as the CEO of a now-embattled company last month. Dramatic changes are needed, and that’s what Gelsinger offered: A plan to bring Intel back from the brink of relevance.

Intel has a plan

Gelsigner’s presentation was an odd mix of alarming and exciting. Intel is spending $20 billion to build two leading-edge fabrication plants (fabs) in Arizona, which will be “EUV capable,” meaning they’ll be able to produce chips at 7nm and lower. It also plans to expand on that with further fabs in the US and Europe.

At a time when global semiconductor supplies are both extremely strained and largely concentrated in Taiwan, that’s huge news. President Biden has of US supply chains for semiconductors, and while Intel was clear there were no government incentives in place just yet, it says it’s “excited to be partnering with the state of Arizona and the Biden administration on incentives that spur this type of domestic investment.”

Walden Kirsch/Intel

While expanding its chip-making capacity is to be expected, what’s really interesting is that Intel also plans to use its fabs to make chips for companies like Qualcomm and Apple, which are both currently reliant on TSMC. Rather than selling Apple its own processors, though, Intel would act as a foundry that builds chips to Apple’s design blueprints. It’s not the first time that Intel has tried the foundry model, but from Gelsinger’s presentation, this now appears to be a cornerstone of its business plans moving forward. If you can’t beat ‘em, build for ‘em?

On the consumer side, Gelsinger spoke of the need to “reestablish tick-tock discipline,” referring to the old Intel edict where each year would see an improved processor, either with a new architecture or built on a fresh manufacturing process. This model was successful from 2006-2015, but has utterly fallen apart since. He claimed we’ll see 7nm Intel processors in 2023 and, in a bit of a shock to those who don’t follow the CPU rumor mill, publicly acknowledged that Intel would need to outsource production of some of its CPUs to get back to the top.

A ‘pathway to parity’

In a particularly telling moment, Gelsinger noted Intel now has a “pathway to parity,” which isn’t exactly the best pitch it could make to prospective clients and investors. The challenge for Intel is that TSMC is working to increase both its capacity and geographic reach, part of which includes building a fab in… Arizona. Then there’s Samsung, which is aggressively expanding its foundry business, including building leading-edge fabs in the US. While it’s unlikely that Samsung will overtake TSMC technologically, it is working very hard to both stay competitive and increase its capacity.

A quick aside: Samsung, TSMC and Intel all equip their foundries with machines from ASML, which is currently the sole supplier of EUV fabrication equipment, a necessity for leading-edge fabs. So, as well as competing for clients, these companies are also competing for resources. ASML is expanding production, but so far they’ve only shipped just over 100 EUV machines, which is yet another potential bottleneck. We talked a bunch about EUV, Intel, TSMC and ASML in an episode of our Upscaled explainer show last year, which is worth checking out if you want to know more.

Back to Intel: Gelsinger wants the company to be in a position of “unquestioned leadership” by the mid ‘20s. Quite how it gets there is up for debate. I mean, TSMC is producing 5nm chips right now. As I hinted at earlier, it’s near-impossible to compare “nm” figures across manufacturers, so it’s tough to know where Intel 7nm will stack up against TSMC 5nm. The easiest figure to compare is transistor density where, if I had to guess, Intel 7nm will probably land ahead of TSMC 5nm. That would be great if it was ready now, but TSMC plans to be in volume production on 3nm in the second half of next year, so chances are it’ll be in the same ballpark before Intel is ready.

So, things are not going to turn around overnight. Indeed, the immediate future looks fairly bleak. When Apple swaps its high-performance Macs over to its own chips it will be jumping from 14nm Intel to, mostly likely, 5nm TSMC chips. Apple’s CPUs are, by all accounts, extremely innovative and good in their own right — again, we did in our Upscaled show — but definitely benefit from being physically more dense and power efficient than Intel’s. While we don’t know the scalability of Apple’s architecture, the basic math suggests these high-performance Apple processors should be able to outmuscle the chips they’re replacing. In the eyes of the public, it’s likely to be another humiliating moment for Intel.

Away from Apple land, AMD is thriving, although the market swing towards the company has currently stalled, as global chip shortages effectively mean people can’t buy its processors. As with Apple, AMD’s strength didn’t just come from TSMC’s manufacturing clout. It switched to a heterogeneous “chiplet” architecture in 2017, which allowed it to rapidly and cheaply scale the number of cores and SKUs in its lineup. And with almost every generation since, it’s improved the efficiency of that design. The latest Ryzen chips essentially boosted performance by around 20 percent over the processors they replaced, despite being fabricated on the same TSMC process.

Intel, too, has superb engineers — the fact it’s been able to do so much with 14nm is a testament to that. It debuted its first 14nm chips in 2015, a lifetime ago in technology. By the end of 2015 its consumer desktop line topped out at the four-core, 4-4.2GHz 6700K. Today, its incoming flagship 14nm desktop chip is the 8-core, 3.5-5.3GHz 11900K. While Intel’s 14nm manufacturing platform has improved in that time, what we’re mostly looking at is a bunch of very talented engineers working past some very difficult engineering problems.

Part of Intel’s success at 14nm has come from just plain throwing more power at its chips. In desktops, even if it’s better to use less power, this is pretty much fine. You’ll notice high-end PCs coming with some pretty exotic cooling compared to their 2015 equivalents, but beyond that inconvenience, it’s not been a deal-breaker. In devices like laptops, though, the power situation has meant that users really are choosing between performance and battery life in a much more linear fashion than should be necessary. Intel has fought valiantly to improve its mobile chips, and many thin-and-light machines are actually running on 10nm. It’s not sitting still, but you need only glance at a MacBook Air or an AMD-powered gaming laptop to see that there’s only so much it can do right now.

Intel

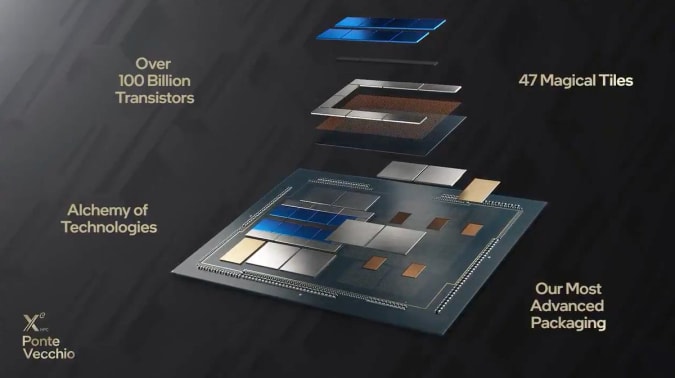

Down the line, Intel will be moving away from monolithic processors, towards something between Apple and AMD’s approach. Rather than employing “chiplets” of high-density cores with other lower-density parts, though, its 3D Foveros technology stacks different “Tiles” together. We got the first last year, and Intel sees it as a key differentiator moving forward. When you pair this with its focus on delivering leading, rather than “good enough” graphics, it’s easy to see Intel’s vision here: To deliver “system on packages” that, like Apple’s M1, squeeze almost everything a computer needs into one efficient and fast die.

The lingering doubts

Between Intel’s renewed focus on fabrication, its consumer roadmap and its willingness to rely on external help from the likes of TSMC and Samsung, Gelsigner has all the right ingredients to take the company back to the top of the industry. It won’t happen overnight, but Intel doesn’t need it to. This is a wildly profitable company, and despite committing tens of billions of dollars to these efforts, it will continue to be so for years to come. The changes are coming before the bottom-line impact, which is important.

There are still major questions to be answered. Apple has all-but given up on Intel, and more partners than ever are using AMD — how much goodwill is left to switch back, especially before Intel has a superior foundry product? TSMC is an extremely well-run company, with a culture of relentless progress instilled by its founder Morris Chang. It got to where it is today by being a pure-play foundry that prices aggressively and doesn’t compete with its clients. Beyond its 3nm launch, it has plans for 2nm, 1.4nm and 1nm this decade — it won’t be sitting still waiting for Intel to catch up, and neither will Samsung.

Intel

Intel’s key negotiating tool will likely be that it’s American, and operates foundries in the US and Europe. In today’s Sinophobic tech environment, that counts for a lot — even though neither TSMC nor Samsung is a Chinese company. It also says its foundries will be a separate business with its own balance sheet, an approach that Samsung uses to good effect in both the display and NAND industries. For US companies like Apple, Qualcomm, Google and Microsoft (which is reportedly designing its own ARM chips right now), partnering with Intel will be great PR and could improve supply chains, both in terms of reliability and security. (Although, as mentioned, both TSMC and Samsung are expanding their US foundry efforts.)

The big problem is trust: For the decade I’ve worked in tech journalism, Intel has consistently failed to deliver on its promises. As a writer that’s tough, as I always feel the need to couch any Intel story with “ifs” and “buts.” As a consumer, avid PC gamer and current AMD CPU owner, though, a lack of follow-through has left me very unlikely to return to Intel any time soon. How many times have we heard that Intel was going to get back to “tick-tock”? And my opinion is not important compared to that of key partners like Apple, ASUS, Dell and Lenovo, who have all been similarly burned by Intel’s technological failures in recent years. Even once Intel catches up technologically, it will need to convince prospective clients that it can deliver on promises and that dealing with a direct competitor is good business.

A lack of follow-through has left me very unlikely to return to Intel any time soon.

At least Intel can now show that it has a plan. It hasn’t chosen the easiest route, but it’s one that, if executed properly, can lead it back to the top. And its vision will most likely be welcomed: Politically, the US is begging for manufacturing jobs and semiconductor supply. On the industry side, even if TSMC could meet the entire industry’s semiconductor demands, you need multiple players to keep prices in check and innovation rolling. As for me and you, the benefits are two-fold. Firstly, AMD, NVIDIA, Qualcomm and even Apple have it easy right now, and we need Intel to push them hard on CPUs and GPUs. Secondly, we’re in the middle of a global chip shortage that’s causing next-gen consoles, CPUs and GPUs to sell for multiple times what they’re worth. The resurgence of Intel should play a major part in ensuring we don’t end up in this situation again. A strong Intel is exactly what the tech world needs right now — let’s hope it can actually follow through.

[ad_2]

Source link